Electric skateboard motor – How to choose an electric skateboard motor?

Introduction

We’ve got to admit that skateboarding is a lot of fun! Especially now that electric skateboards have hit the mainstream, they are more fun than ever before! There’s a language that all skateboarders know extensively. It gives the skateboarder a close connection between his peers and the road – as with the wind that’s flying against the skater’s face as he rides into the sunset.

Choosing an electric skateboard can be a grueling task! Each board is catered to different riding needs and abilities. Some skateboarders prefer a skateboard that is longer. Others prefer a board that is shorter. Some prefer a skateboard that can go on rough terrain… One thing that electric skateboarders rarely talk about is the different types of motors one can get.

If you’re not an alien to the world of electric skateboarding, you will know what skaters talk about in terms of their board capabilities. Skaters like a board that can handle well in different conditions – especially electric skateboards that can go uphill at really high speeds. Learning about motors is one of the most important aspects of e-skating. This is because it is important to know how each and every little piece of your electric skateboard works.

Electric skaters will need to decide on what type of electric motor is the best for their riding abilities. So, we decided to write this article to give riders the knowledge needed to make an informed choice.

Today we are going to discuss the differences between the types of electric skateboard motors available. The most important issues for an electric skateboarder are range, speed, and maintenance. In this article, I will be giving you an overview of what each motor is and how they work.

The belt-driven motor was one of the first electric skateboard motors invented – which is fantastic for a skater! One of the brilliant things about these motors is that they were very noisy – something a lot of electric skaters like. The main problem with these motors is that the belts wear out quite easily; the good thing is you can exchange the wheels with standard skateboard wheels. This is great because they have a longer shelf life.

Hub motors are a lot quieter as the motor is inside the wheel itself. This is a problem though. When a wheel breaks it has to be replaced with a polyurethane sleeve! The problem with this motor is that, if you’re an avid skater, the polyurethane sleeves wear out very fast and needs to be replaced.

The direct-drive motors are the best of both worlds. These motors have as much torque and pull as belt-driven motors but without noise. Also, you can exchange with a standard skateboard wheel.

In this article, we are going to discuss the specs and how these motors work, to give you an idea of what type of motor you would like for your riding style.

Belt Driven Motors

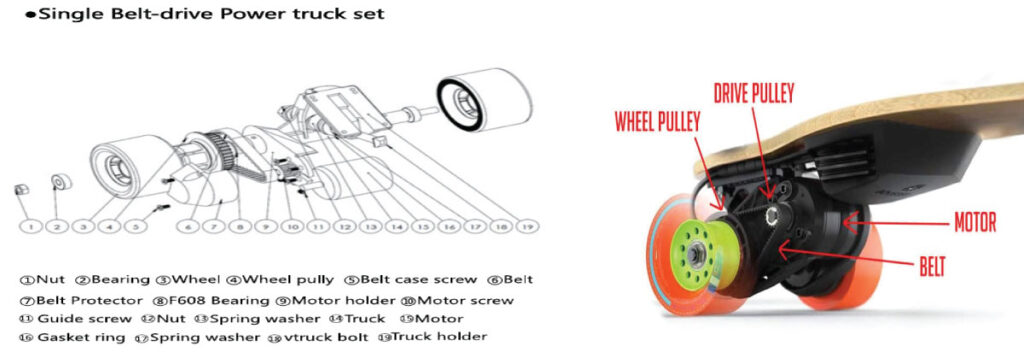

Belt-driven motors are known as flexible machine elements. This type of element is able to handle any type of shock and vibration. They were first introduced into combustion engine motorcycles, and are the most traditional drivetrain.

The primary function of all belt drive systems is to get a transmission of power from a source such as an electrical engine or a combustion engine. There’s a belt attached from the motor to a cog or flywheel, and this is attached to a wheel. When the motor is in motion it would spin the driveshaft and pulley system to the wheel.

Skateboard belt motors originated from children’s toys, from cheap remote control cars to autonomous drones. Skateboard Belt drive motors utilize an externally mounted motor with a gear-like pulley and belt to create a gear reduction on the motor before transferring power to the wheels. The motors are attached separately from the wheels, via a bracket on the trucks. There is a gear on the motor shaft and gear on the running wheel. Attached to the gear is a rubber belt connecting the two together. The motor rotates the wheels via a belt, similar to the same way you would peddle a bicycle.

The concern about belt-drive motors is the noise that they produce. They are limited to the free-rolling ability, which means if the battery is dead then it can’t be ridden. Since the belt drive system has a significant amount of resistance it can make it harder to kick push due to the presence of pulleys.

Pros

A belt drive naturally allows for an input gear on the motor and an output gear on the wheel. The brilliant thing about this is that you can change the size of these gears and this will increase the torque manipulation from the motor. If you think in terms of when a gearbox changes gears on a motorcycle it is changing the manipulation of the torque so the engine can cope with the terrain. Belt-driven electric skateboards can be modified to have a lower or higher gear for more or less resistance to the belt drive motor. If you live in a street with a lot of hills then a belt drive system is the best choice.

The brilliant thing about belt drive is the wheel options. Belt-driven boards will always give you more options in terms of wheels because the motor is separate from the wheel itself. This gives you a larger range of wheels to choose from and the wheels themselves will last longer compared to a hub wheel.

The belt-drive motor is connected to the truck system via a bracket mount. This is open to circulating air when you are riding the board. It also provides better heat dissipation and stops the motors from overheating. Belt-driven motors run cooler than hub motors due to natural ventilation. This is because motors stand at the bottom or top of the truck.

Cons

First of all, belt-driven motors are loud. The belt itself will make a lot of noise, but some people actually prefer this as it sounds “kool”. We know for a fact that in some areas people complain about the noise these boards make.

Belt-driven motors do require more maintenance as the board itself has more moving parts. The belts will last 300 to 600 miles. This is before they have to be replaced. The good thing is that the belts are cheap and usually with any electric skateboard purchase comes with spares. The belt is also susceptible to dirt, sand, and pebbles. This can cause the belt to snap. Replacing the belts is not too difficult htough.

A skater must know about electric skateboard maintenance as this is an important step. When a belt does snap you will not be able to ride belt-driven motors as a normal longboard or skateboard.

Belt-driven motors are hard to ride without the assistance of battery power and are almost impossible to push the board. The gear drive provides an advantageous lever while the motor is running but magnifies the friction in the motor while it’s not running. If the battery dies you will have to carry the skateboard home…

Also, belt driven motors run hotter than direct drive motors.

The Hub Driven Motor

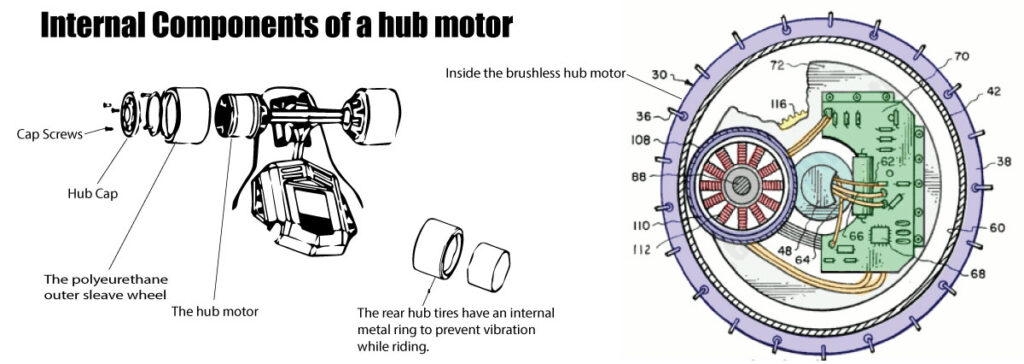

The most common types of motors are Hub Motors, which are available on the market. Hub driven motors are popular within the skate community because it is relatively less expensive in parts, its clean and simple implementation. They are also quiet, stealthy, and have a huge market appeal.

The Hub Driven Motors is embedded into the wheel. The motor is sitting on the truck drive shaft and the wheel is surrounded by a thinner ring of polyurethane. They work by applying torque directly to the wheel while belt-driven motors transfer the power through gears via belts and chains.

They have a poor shock absorption system and this makes the board less comfortable for riding. The braking system is not as efficient as a belt system. The motor has a poor torque acceleration speed compared to other systems out there.

Manufacturers can create an electric skateboard that does not look bulky and resembles a standard skateboard. Belt drives make the board look bulky and unnatural in a way.

These types of skateboards usually come with replaceable urethane sleeves. The Hub wheels are sold by the manufacturer. These thin urethane wheels are actually at a disadvantage because you have to buy them directly from the manufacturer and you cannot replace the skateboard wheels with any type of skateboard wheel that is out on the market.

Pros

A hub motor is sleek and looks like a normal skateboard wheel. They produce less noise than all three motors combined.

The sleeves do not cost that much to replace as they are only a thin layer of polyurethane. Replacement sleeves are easier to come by as they are very common now within the market. A lot of sleeves are generic between the different manufacturers and can easily be replaced.

Replacement sleeves are easier to come by as they are very common now within the market. A lot of sleeves are generic between the different manufacturers and can easily be replaced.

These motors are more durable and don’t require as much maintenance as rubber belt-driven motors, which need belts and gears to be replaced every 300 to 600 miles. Belts are high maintenance consumable items and generate noise.

Hub motor skateboards can be ridden like a normal traditional skateboard. This is very handy if you run out of battery or the motors are out of commission. This also saves you from walking home at the end of the day!

Cons

A hub motor does not have as much tongue and acceleration power as a belt-driven motor. If we were to race a hub motor with a belt-driven motor uphill, the belt drive motor would win almost every time.

The thin ring of polyurethane wheels is actually a disadvantage because the wheels wear out more quickly than a regular skateboard wheel. The wheels to replace are expensive to buy compared to belts and tend to not last as long as your belt-driven counterparts.

out more quickly than a regular skateboard wheel. The wheels to replace are expensive to buy compared to belts and tend to not last as long as your belt-driven counterparts.

Rear wheels can’t be replaced with normal skateboard wheels. I find this to be a massive disadvantage because skateboarders would like to change their wheels dependent on the terrain they wish to ride. If I wanted to ride a rougher tarmac, then I would have to replace the wheels with a softer polyurethane compound or with all-terrain wheels at a 100mm x 65mm diameter.

Hub motors run very hot compared to belt-driven motors and direct drive motors. This is due to a lack of ventilation in the wheel which prevents the motor from being cooler.

/cdn.vox-cdn.com/uploads/chorus_asset/file/19446652/dotBoard_Hero_FPO.jpg)

Direct Drive Motors

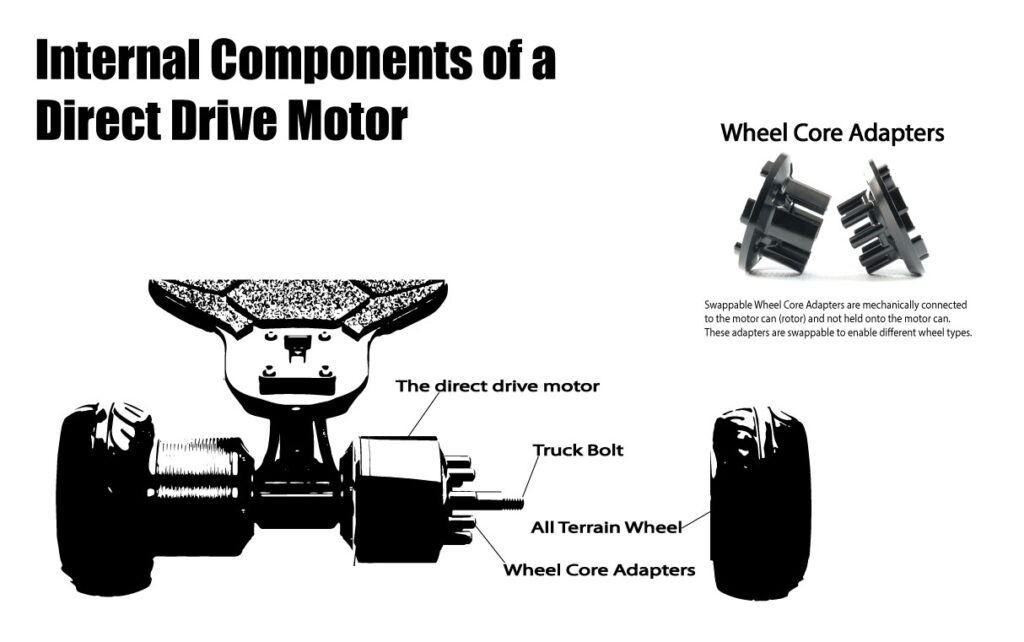

A Direct Drive motor is a system where a full motor directly drives a full wheel. Direct drive motors are not as common as the other motor types. They work in a similar way to hub motors. They apply torque directly to the wheel but the motor is not inside the wheel itself. It is located on the side of the wheel and mounted directly on the trucks.

This motor has a big advantage over hub motors because they are not inside the wheel. The biggest advantage of this type of motor is it can work with any skateboard wheel – as long as the wheel has the correct adapter inside it. You can buy any wheel you like depending on the terrain you decide to ride. Skateboarders love this option as it gives them a choice of different types of wheels.

The wheels are the standard longboard or skateboard wheels. This means you can take advantage of the thickness of the urethane wheels. The wheels themselves will not wear as much as the hub motor wheel though. Skateboarders will have the option to exchange the wheels whenever they like.

Pros

Direct drive ascetically looks better as a motor than a belt drive but they are not hidden away compared to a hub motor. They are less common than all three motors but this is because they are a newer design.

Torque is direct to the wheel. The motors can be bigger than hub motors which means you are able to fit a bigger motor in its space. This means that some of the motors can produce more power and torque compared to the hub and belt-driven counterparts. The problem with belt motors is that they sit on the side of the truck or above the truck via a mounting bracket. If they sit next to a truck they are more subjected to rocks and damage. For this reason, the motors cannot be as big as the direct drive. The advantages of direct drive systems are:

- Swappable wheels.

- Full use of full urethane wheels.

- Free-rolling unlike belt drives and generally run a quieter system.

The wheels can be exchanged with a normal longboard or skateboard wheel. This gives you the option of changing the wheel when you need it. Hub sleeves do not last as long as a full-scale skateboard wheel. This is why a lot of riders prefer direct-drive or belt-driven motors.

The motors run cooler compared to the other motor types. This means they have fewer overheating issues compared to other counterparts.

Cons

The direct drive system might seem like the best electric skateboard system, but it also comes with some disadvantages. The direct-drive motor isn’t shielded and sits right next to the wheel. Due to the fact this motor is not shielded, the ground clearance is affected which means the motor may get severely damaged on rough terrain. One of the big disadvantages is the motor is big and bulky and can affect your ride if you ride over rocks. You will tend to get scratches on the bottom of the motor because of the surface clearance.

The direct-drive motor isn’t shielded and sits right next to the wheel. Due to the fact this motor is not shielded, the ground clearance is affected which means the motor may get severely damaged on rough terrain. One of the big disadvantages is the motor is big and bulky and can affect your ride if you ride over rocks. You will tend to get scratches on the bottom of the motor because of the surface clearance.

The motor is a bit louder than hub motors but not as loud as belt-driven motors. I wish they made a direct drive motor with a gearbox inside it. This will give you more torque if you are riding uphill which is what belt-driven motors are good for. With belt-driven motors, you can change the gear ratio depending on what size wheels you place on the truck. Unfortunately, you cannot do this with direct drive as it doesn’t have a geared system. Having said that, these motors can go uphill pretty well! It performs better than the hub motor and can keep up with the belt-driven counterparts.

They use a full wheel of urethane, unlike hub motors which employ the use of urethane sleeves. They are extremely heavy in nature and one of the major culprits for this is the steel axle.

How to choose a motor?

Making a choice for electric skateboard motors is not an easy task. You have to first work out what type of motor best suits your riding needs. It is important to note that there is no best overall motor. There are only suitable motors based on the type of motor that you are looking for within the market.

Here is a list of motors based on a number of factors.

Noise – Direct drive and hub motors are two of the best for noise reduction. If you are a rider that worries about noise from the motor while whizzing past people at campus then I would suggest one of these motor types. Hub motors are also quiet. One thing to recognise is if the motor is a single or a dual motor setup as this will affect the noise coming from the board.

Torque – Belt drive motors deliver the best torque compared to all the others. They have a better acceleration speed and can climb hills very quickly.

Conclusion

For riders who like to ride uphills fast with small wheels, I would recommend a belt-driven motor. I feel it is slightly better for this type of situation, although for reliability I would prefer a direct drive motor. I find this motor has the best of all belt motors and hub motors without issues such as overheating or wear and tear.

The brilliant thing about the direct drive is that it’s cooler than the others and you can change the wheels when needed. A skateboarder will love this idea! You can also ride this electric skateboard as a normal skateboard which you can’t do with a belt-driven motor. It almost has as much torque as a belt drive. A direct drive is quieter than a belt drive.

Hub Motors are cheaper in upfront costs and there a lot of manufactures out there producing them. A lot of cheaper skateboards have this type of motor fitted. Beware though, as the motor sleeves will have to be replaced every year if the board is ridden regularly.

Please leave a comment on our webpage or twitter feed below! Follow US on Twitter @ElectricMicrom1 for the latest News & Reviews.

Recent Comments